The Technologies that make robotics possible work together. Robots require power, they need electronic sensory & control systems, along with mechanical automation systems The next few posts will be about the various motors used in robotic automation systems. Precision, speed, form factor, torque, voltage, and availability are all factors that go into decisions on what motor is to be used for each robotic application.

Controllers not only activate motors they may energize solenoids or relays.

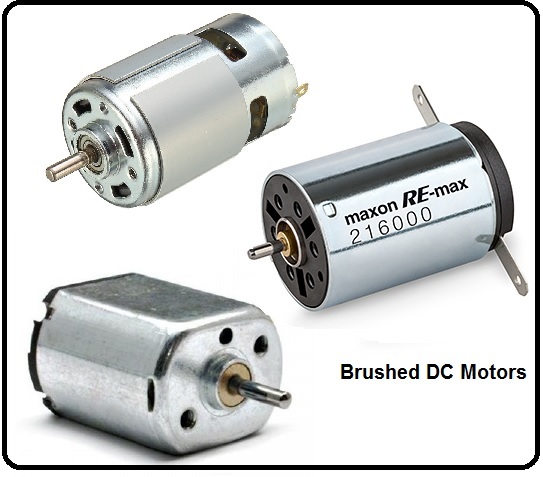

A drive referred to as an actuator is a device which converts energy into physical motion. The drives in a robot are used to move its wheels, tracks, turrets, legs, and manipulator components. Drives are powered from a main supply. Common preferred voltages for DC motors are 3, 6, 12 and 24 Volts. The motor operation allowing robotic automation is controlled by relatively low energy pneumatic, hydraulic, electronic or manually generated signals.

The drives are generally motors the kind of which depends on the specific application. Following are the pros and cons of the various types of motors:

AC Motor | Brushed DC motor | Brushless DC motor | Geared DC motor | Servo motor | Stepper motor |

· Stationary systems | · Toys· RC Servos· Gear Motors | · Multicopters· Drones· Radio Control Vehicles· Disk Drives· Fans· Industrial Servos· Hybrid Vehicles· High-End Gearmotors | · Robot Drive Trains· Radio Control Vehicles· Cordless Tools | · Robotics· Animatronics· Radio Control Cars/Boats/Planes | · 3D Printers· CNC Machines· Camera rigs Robotics· Printers· Precision Gearmotors |

· Inexpensive· Lightweight· Reasonably Efficient· Good low-speed torque | · Quiet· Efficient | Speed ReductionIncreased Torque | Low costVarietySimple to control | · Precise repeatable positioning· Precise speed control· Excellent low-speed torque· Excellent ‘holding torque’ to maintain position |